Drum sander maintenance and specifications

Jump to navigation

Jump to search

|

Shop Area: Woodshop Tool: Drum Sander Requires in-person training: Yes |

Procedure Number MT 110-10, Rev. 0 |

Date 4/19/2021 |

General

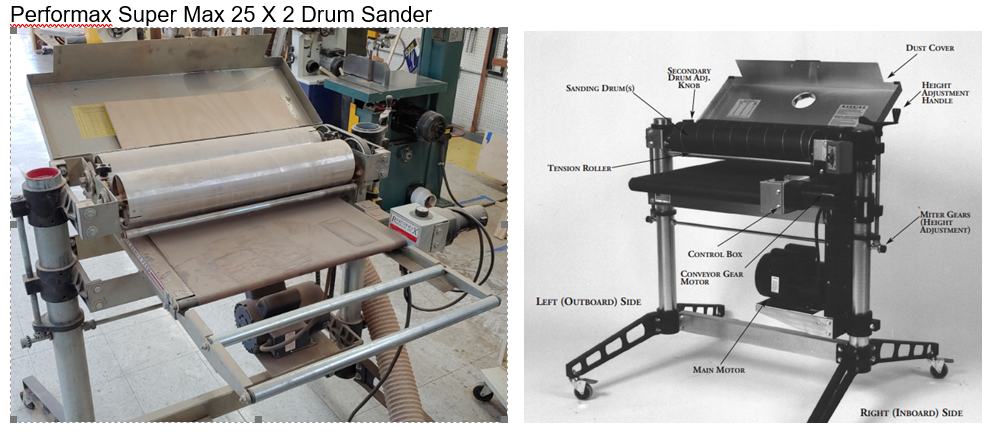

We have 3 Drum Sanders, see details below. This guide provides information based on the Performax Drum Sander and are similar to the use of the Jet Drum Sanders.

Reference

Maintenance

Perform the following recommended maintenance procedures on a monthly basis:

- Lubricate conveyor bushings and check for wear.

- Lubricate all moving parts, such as threaded rods, washers, and column tubes.

- Clean sawdust from the sandpaper and the conveyor belt.

- Blow dust from the inside of sanding drum(s) and the motors.

- Check all set screws for tightness on parts such as table support castings, bearings, conveyor coupler, castings, pulleys, and miter gears.

Cleaning Abrasive Strips. Regularly clean the abrasive strips on the drums with commercially available cleaning sticks, following the manufacturer’s directions. When cleaning, also brush the stick crumbs from the drum while it is still rotating.

Specifications

END OF THE PROCEDURE